-

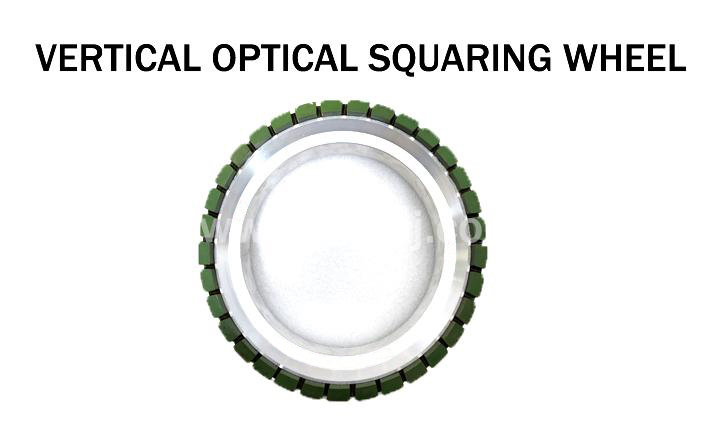

VERTICAL OPTICAL SQUARING WHEEL

1. Long working life, sustainable sharpness, and low working noise.

Send Email Details

2. Strict technological process control ensures stable quality.

3. According to customer feedback, the product demonstrates stable performance in processing.

Application: Suitable for precision grinding of high-end products in the optical industry. -

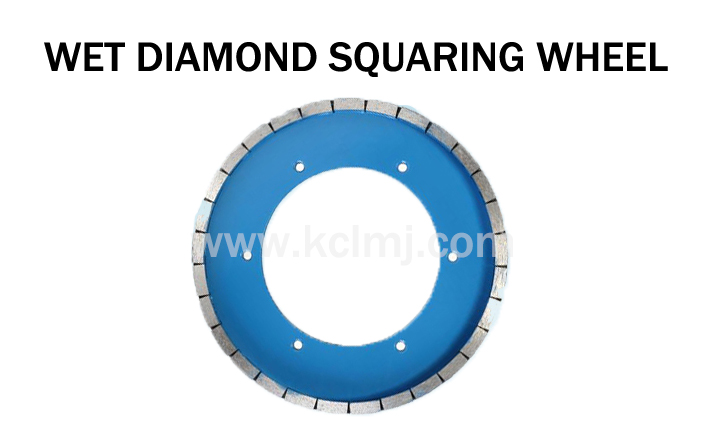

WET DIAMOND SQUARING WHEEL

WHEEL DIAMETER(MM) : Ø150*140 (80),Ø200*140 (80),Ø250*140 (80),Ø300*140 (80)

Send Email Details

SEGMENT SIZE W*H(MM): 8×12 10×14

Diamond squaring wheels are mainly used for rectify the tile edges. According to the grinding way, it is divided to tangent wheel and disk wheel. -

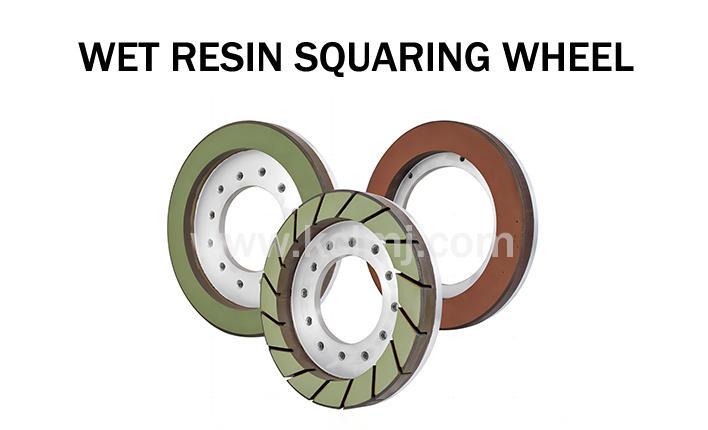

WET RESIN SQUARING WHEEL

OUTER DIAMETER-WORKING WIDTH*HICKNESS(MM) :

Send Email Details

Ø300-40×12,Ø250-40×12,Ø250-35×12,Ø250-25×12,Ø200-40×12,Ø200-35×12,Ø200-25×12,Ø200-20×12,Ø200-15×12

Resin squaring wheel is normally used for fine trimming of tile edges. As a result, the tile edge will be smooth and the corner has no broken chips. -

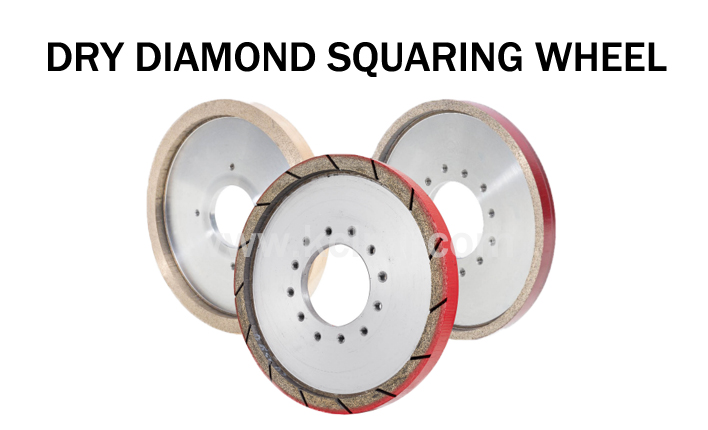

DRY DIAMOND SQUARING WHEEL

We offer special customized manufacturing of high-quality wheels according to client requirements. These wheels feature strong cutting performance and excel at solving problems while maintaining a good working life.

Send Email Details -

DRY RESIN SQUARING WHEEL

Dry squaring wheels, manufactured using the newest formulations and advanced production techniques, fall into two categories: resin bond diamond dry squaring wheels and diamond bronze ring gears. These wheels, part of the fine squaring series, ensure good verticality and precise specifications when processing tile edges. They reduce edge chipping, produce smooth and straight bevels along the tiles, and offer high sharpness, universality, good wear resistance, stable performance, and excellent finishing effects.

Send Email Details